For Bells, Hubs, Flanges, Couplings and Clamps

One Sleeve Fits All Hubs and Bells, Leaking Joints on IPS, DIP, CIP and PVC Joints, Asbestos Cement Collars. Also encapsulates old couplings, repair clamps and other old leaking repair devices. Nearly all pipe diameters are covered by one sleeve in the 4” to 12” diameters while providing up to 1.3” of range and 4 degrees of dynamic deflection per end. Diameters covered include IPS, DIP, CIP, and AC (asbestos cement diameters including class 200).

The Ultra-Sleeve for Joint Repair and Encapsulation is available in sizes from 2 to 24” diameters.

A quick 20-30 minute installation is enabled by top facing bolts and no end gland bolts to tighten. The Ultra-Sleeves® patent pending two piece end seal and top facing bolts provides a wide range capability in the 4 to 12” sizes. The 16” and 24” sizes are dedicated range products built to accommodate either ductile iron or cast iron pipe diameters. For other diameters above 12” call Total Piping Solutions, Inc for availability. The Ultra-Sleeve® in any diameter makes for it an easy way to repair a leak on any joint and eliminates the need for a complete shut-down of the system.

Asbestos Cement Pipe is handled in all sizes with one sleeve in sizes 4, 6, 8”. In 10” and 12” use under size for metallic diameters and oversized for asbestos cement diameters.

This product is ideal for repairing a split bell or any leaking joint. No need to shut down the water main. Eliminates the need to disinfect the line.

Description

One Sleeve Fits All Bells in a Nominal Diameter

Total Piping Solutions, Inc., is dedicated to providing innovative products designed to save time, labor and inventory dollars in the water and the wastewater industries.

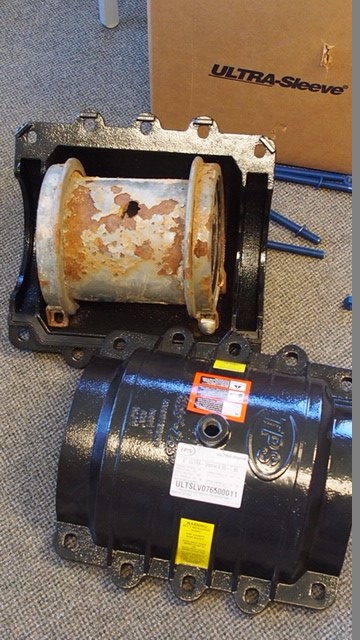

The Ultra-Sleeve® Joint Repair Product is an Encapsulation Sleeve designed for the repair of a split bell, hub or leaking joints including old couplings, old repair clamps, flanges up to 8” in diameter, many MJ style fittings and more. This unique sleeve eliminates the need to shut down the water main, saving on time and repair operations. The sleeve is relatively light in weight, has pre-installed side-bar gaskets and an easy to install dual layered style butt gasket on the end gland while providing up to 1.3” or range. The distinctive design eliminates having to tighten end gland bolts, allowing for quicker assembly. No need to trim or cut gaskets. Simply piece each half together and tighten the bolts for a quick, permanent repair.

Check These Features:

- Wide Range and Long Body – One Sleeve Easily covers IPS/CIP/DIP Bells, Asbestos Cement Pipe Couplings, mechanical Couplings with two or more bolts, repair clamps and more

- Easy to Install – Two Pieces, Easy to Reach Bolts: Tighten the Side Bolts With Standard Wrench

- Eliminate the Need for a Bolted End Gland (Saving Time and Labor During Installation)

- Cost Effective – One Sleeve Works on Multiple Classes (Works on IPS, DIP, CIP, PVC Diameters) AC (Asbestos Cement) Pipe diameters.

- No Need to Shut Off Water Main: Use as a Coupling to Join Pipe Ends or Use for a 360 Degree Encapsulation of the Pipe

Specifications

- Working Pressures up to 200 psi

- Qualification Tested to 1.5X Working Pressure

- Gasket Material: on 2 to 12” diameter sizes is NSF-61 Approved NBR Rubber for Water and Sewer Service, EPDM Gasket material on both the 16” and 24” sizes

- 2-12” Shells of Ductile Iron Construction, 16” and 24” diameters either ductile iron or fabricated carbon steel

- Up to 4 degrees of deflection in sizes from 2 to 12” diameters.

- Temperature Range: -20 degrees F to 80 degrees F

- Nuts, Bolts and Washers: 18-8 Grade 304 Stainless Steel Bolts and Stainless Nuts Coated with Fluoropolymer Coating to Prevent Galling

- Coating – Minimum 10 Mil Fusion-Bonded Epoxy (NSF-61 Compliant)

- 2-12” Equipped with ¾” NPT Vent Plugs on Top and Bottom Shells, 16 and 24” Equipped with 2” Diameter Vent plugs

- One Test Port Plug with Lifting Eye

- Perimeter Bolting and Gasket System (no end glands to tighten)